Mgb e a 100465 escape release mgb e a

Table of Contents

Table of Contents

As an engineer or designer, one of the most critical aspects of creating a technical drawing or blueprint is accurate dimensioning. Dimensioning is the process of adding numerical values to a drawing that reflect an object’s size, shape, and orientation. Without dimensioning, a drawing is virtually useless for manufacturing or construction purposes.

Many people struggle with how to dimension a drawing correctly. Whether you are a beginner or an experienced designer, it’s easy to make costly mistakes that result in errors and rework. Inaccurate dimensioning can lead to product failure, increased costs, and wasted time.

To dimension a drawing correctly, you need to understand the basics of drawing conventions, including how to use different types of lines, symbols, and units of measurement.

Here’s a brief guide on how to dimension a drawing accurately, including some tips and tricks to help you get started.

How To Dimension a Drawing: Step by Step Guide

My first experience with dimensioning a drawing was during my freshman year of college. Our professor had assigned us to create a technical drawing of a simple machine part, and I had no idea how to dimension a drawing correctly.

After hours of research and practice, I finally figured out the basics of how to dimension a drawing. The following steps can help you create accurate technical drawings with proper dimensioning.

Step 1: Understand Drawing Conventions

Before you start dimensioning a drawing, it’s essential to understand the different types of lines, symbols, and units used in technical drawings. Commonly used lines include visible, hidden, center, and cutting plane lines. Each line has a specific purpose and meaning and should be used correctly.

Step 2: Identify Critical Features

When dimensioning, start by identifying the critical features of the object. Critical features are the areas that are crucial to the design’s functional and structural integrity, and their dimensions should be precise.

Step 3: Choose the Right Dimensioning Technique

There are several dimensioning techniques to choose from, including aligned dimensioning, unidirectional dimensioning, and baseline dimensioning. Each technique has its benefits and drawbacks, and you should choose the one that works best for your specific design.

Step 4: Use Clear Text and Symbols

When dimensioning a drawing, use clear and easy-to-read text and symbols for your dimensions. Avoid using overcrowded and overlapping dimensions, and choose a font that is easy to read.

Personal Experience with Dimensioning Drawings

When I first started dimensioning drawings, I struggled with choosing the right technique for my designs. After experimenting with different techniques, I found that aligned dimensioning worked best for me. Aligned dimensioning involves placing dimensions in line with the object being dimensioned, making it easier to read and interpret.

I also found that it’s important to use clear text and symbols when dimensioning. Choosing the right font size and style can make a significant difference in the readability of your dimensions.

Common Mistakes to Avoid when Dimensioning a Drawing

Even experienced designers and engineers can make mistakes when dimensioning a drawing. Here are some common mistakes to avoid:

Using incorrect units of measurement

Make sure you use the correct units of measurement for your dimensions. Using the wrong units can lead to confusion and costly errors.

Overcrowding dimensions and text

Avoid overcrowding dimensions and text, making them difficult to read and interpret.

Omitting critical features

Make sure you do not omit any critical features from your drawing.

Improper use of lines and symbols

Using the wrong type of line or symbol can lead to confusion and errors.

Question and Answer

Q1: What is the importance of dimensioning a drawing correctly?

A: Dimensioning allows engineers and designers to create precise technical drawings that can be used for manufacturing and construction. Accurate dimensioning ensures that the end product functions as intended and meets the required specifications.

Q2: What are the most commonly used dimensioning techniques?

A: Aligned dimensioning, unidirectional dimensioning, and baseline dimensioning are the most commonly used dimensioning techniques.

Q3: What are the consequences of inaccurate dimensioning?

A: Inaccurate dimensioning can lead to product failure, increased costs, and wasted time. It can also result in rework and delays in product development and manufacturing.

Q4: Can computer-aided design (CAD) software help with dimensioning?

A: Yes, CAD software can make dimensioning easier and more accurate. Most CAD software includes tools that automate the dimensioning process and ensure that dimensions are consistent throughout the drawing.

Conclusion

Dimensioning a drawing accurately is essential for creating technical drawings that can be used for manufacturing and construction. Understanding drawing conventions, identifying critical features, and choosing the right dimensioning technique are all critical aspects of dimensioning a drawing correctly.

Gallery

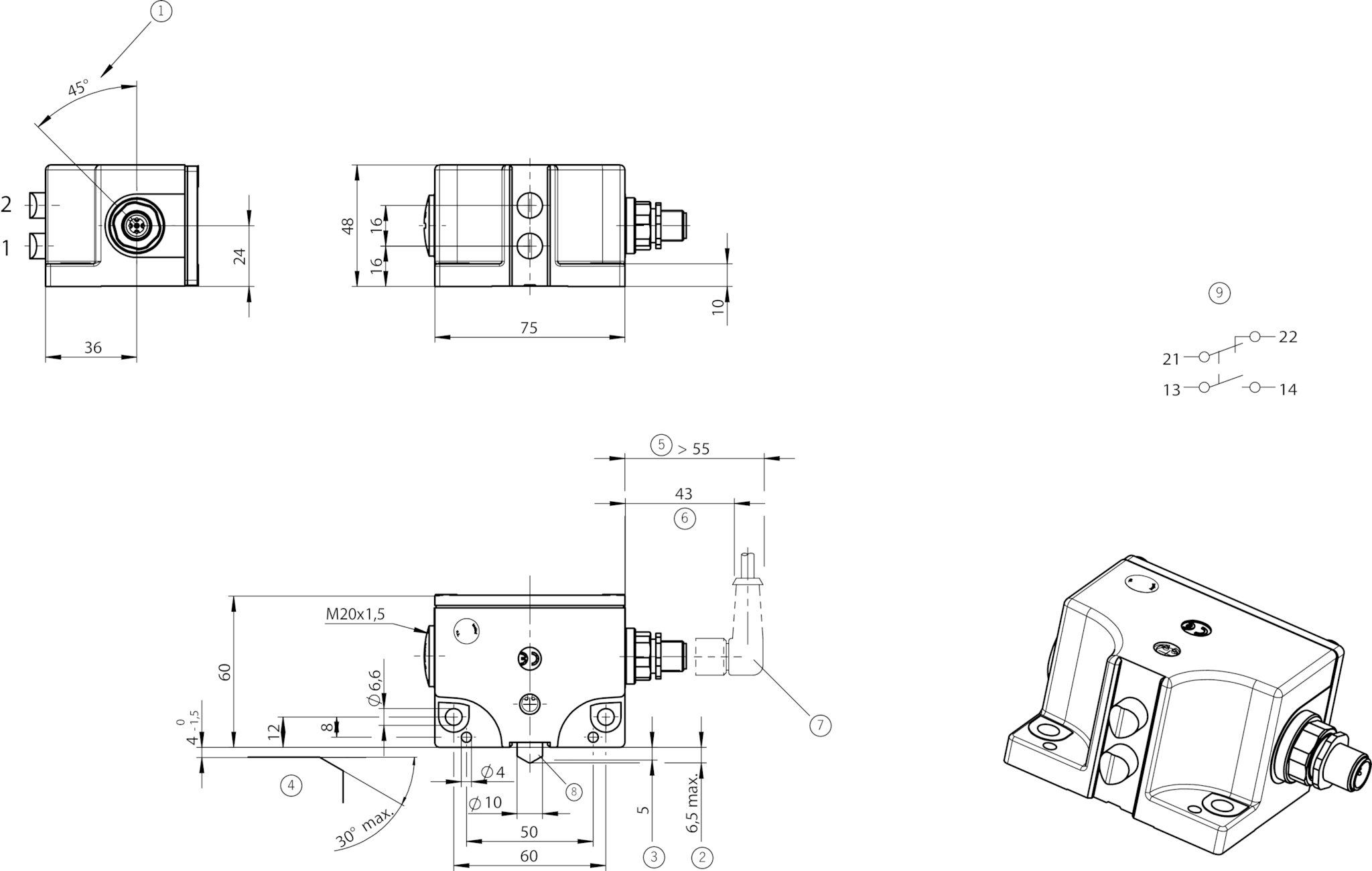

MGB-E-A-100465 Escape Release MGB-E-A… | EUCHNER – More Than Safety.

Photo Credit by: bing.com /

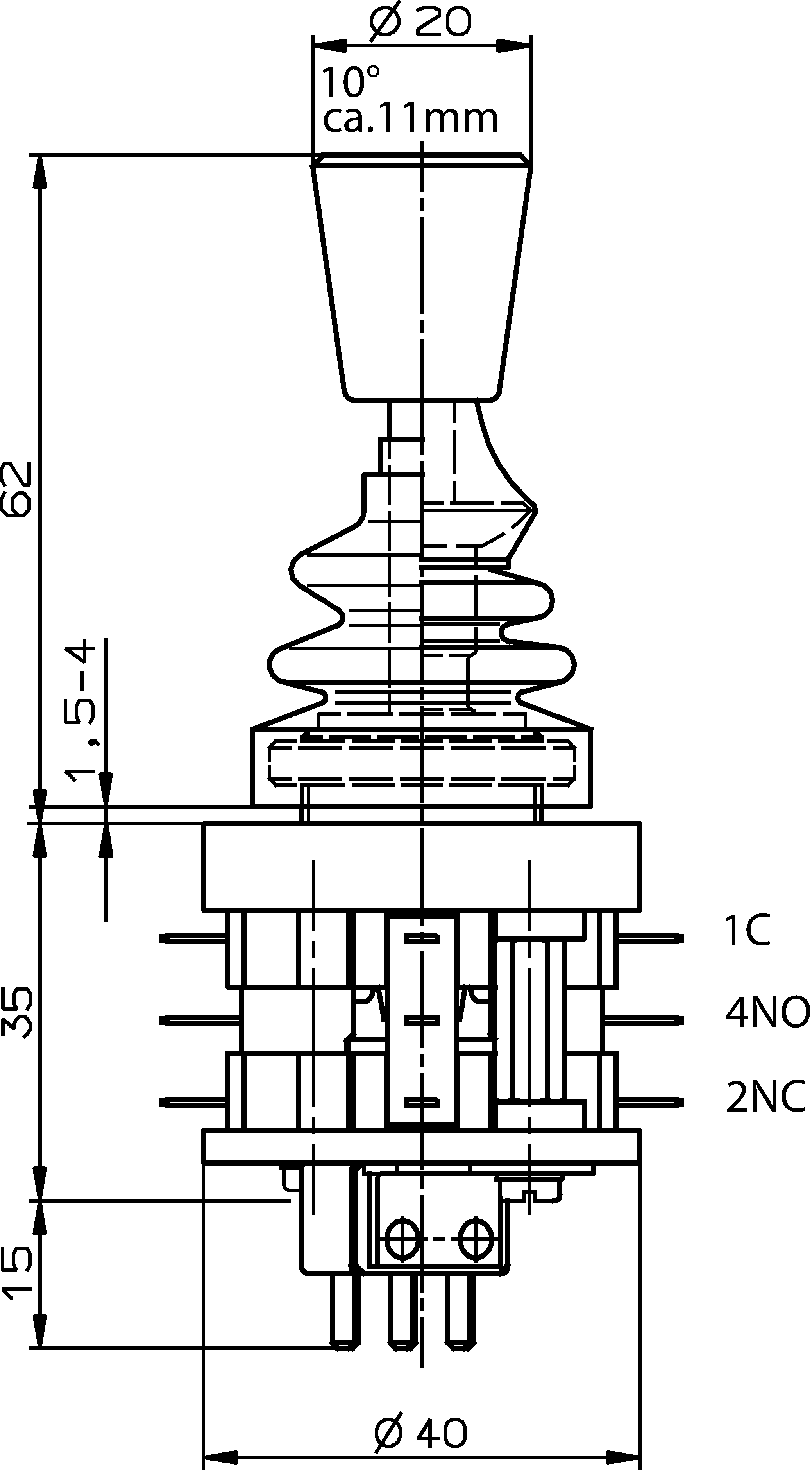

SN02D16-502-MC1938 Series SN… 16 Mm Mechanical | EUCHNER – More Than

Photo Credit by: bing.com / euchner

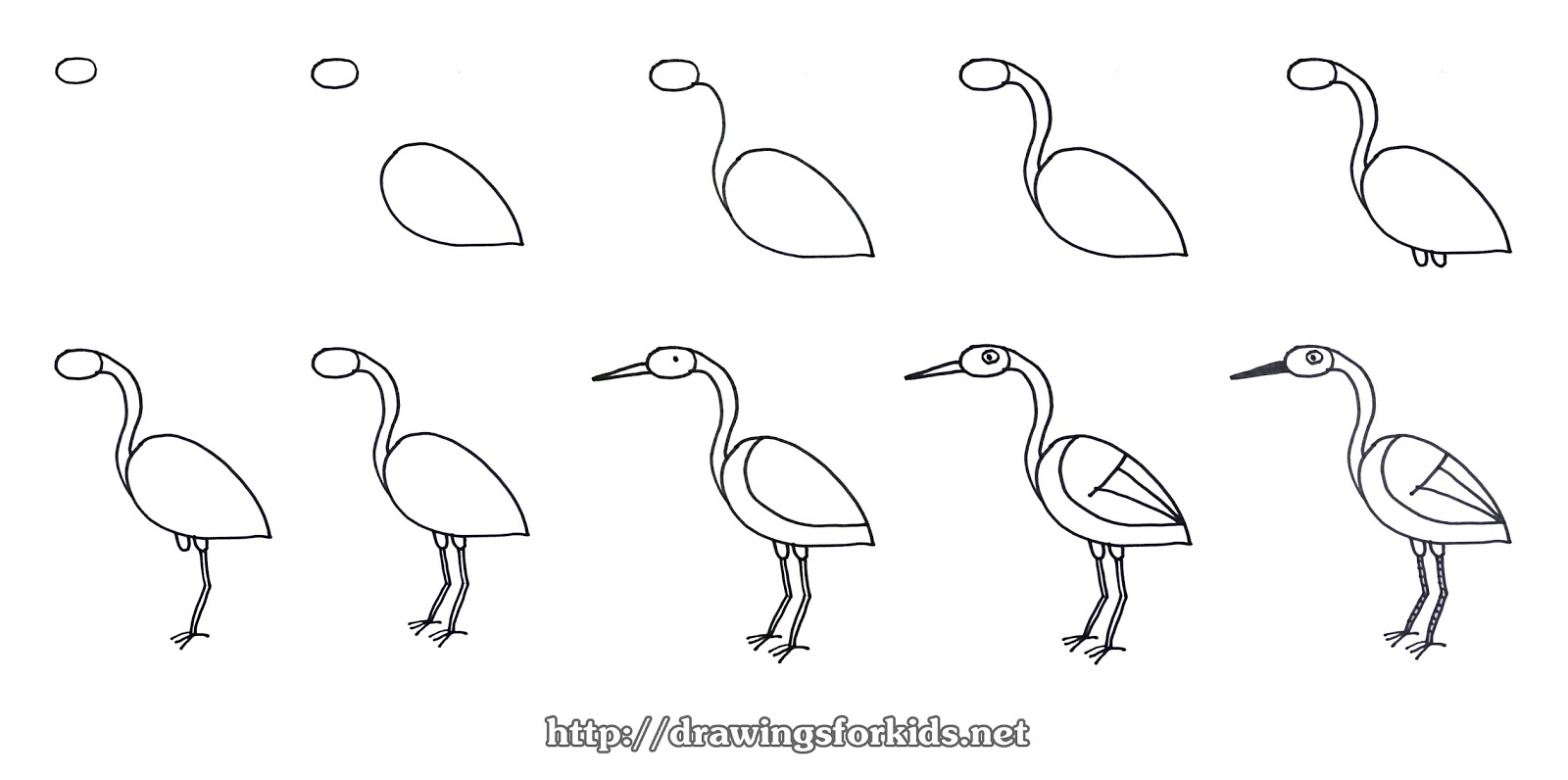

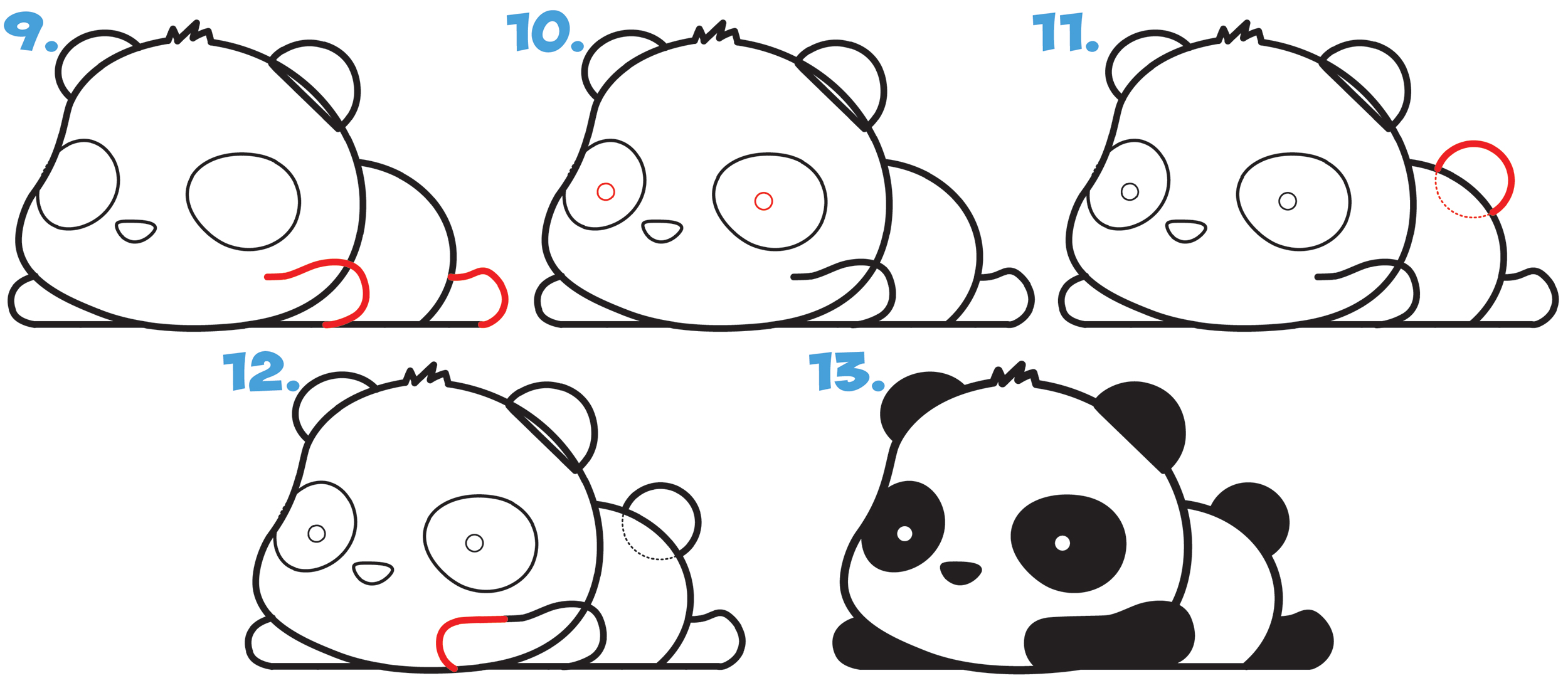

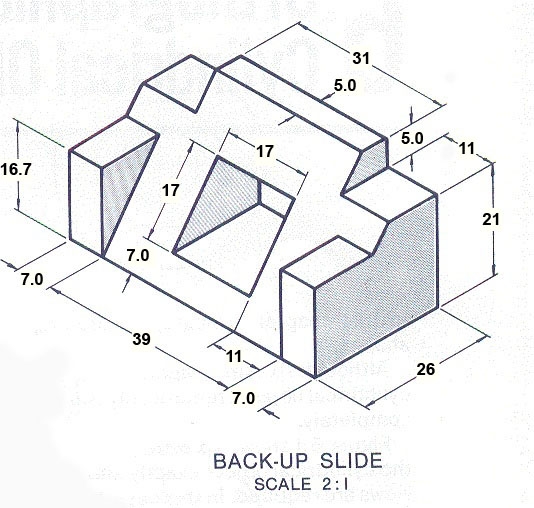

Please Help Me Understand Why The Dimensions On My Drawing Seem

Photo Credit by: bing.com / isometric drawing orthographic drawings engineering 3d cad technical views dimensions sketch worksheets autocad mechanical drafting exercises object dimension slide why

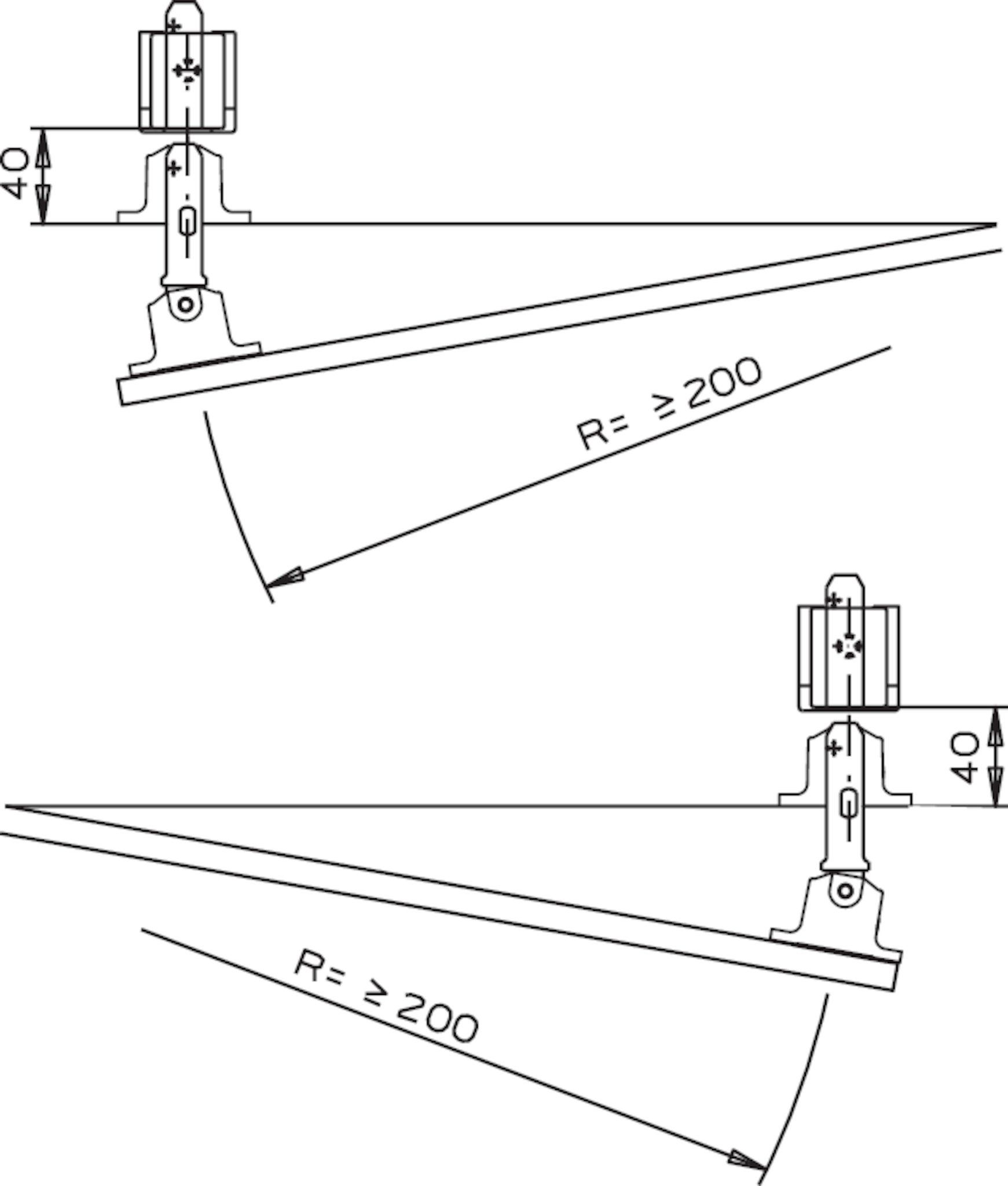

RADIUSBETAETIGER-Z-L-C2194 Hinged Actuator Left For Safety Switches NZ

Photo Credit by: bing.com / actionneur radial vz euchner masszeichnung

KET1234V (Order No. 029715) | EUCHNER – More Than Safety.

Photo Credit by: bing.com / euchner